🌿 Which solvent extraction method is best for dye extraction solution?

Ultrasonic technology can significantly improve the extraction efficiency, for example, in the extraction of baicalin from scutellaria baicalensis, ultrasonic method is better than traditional decocting method, because it does not destroy the molecular structure, and can shorten the extraction time to 20 minutes, while improving the extraction rate

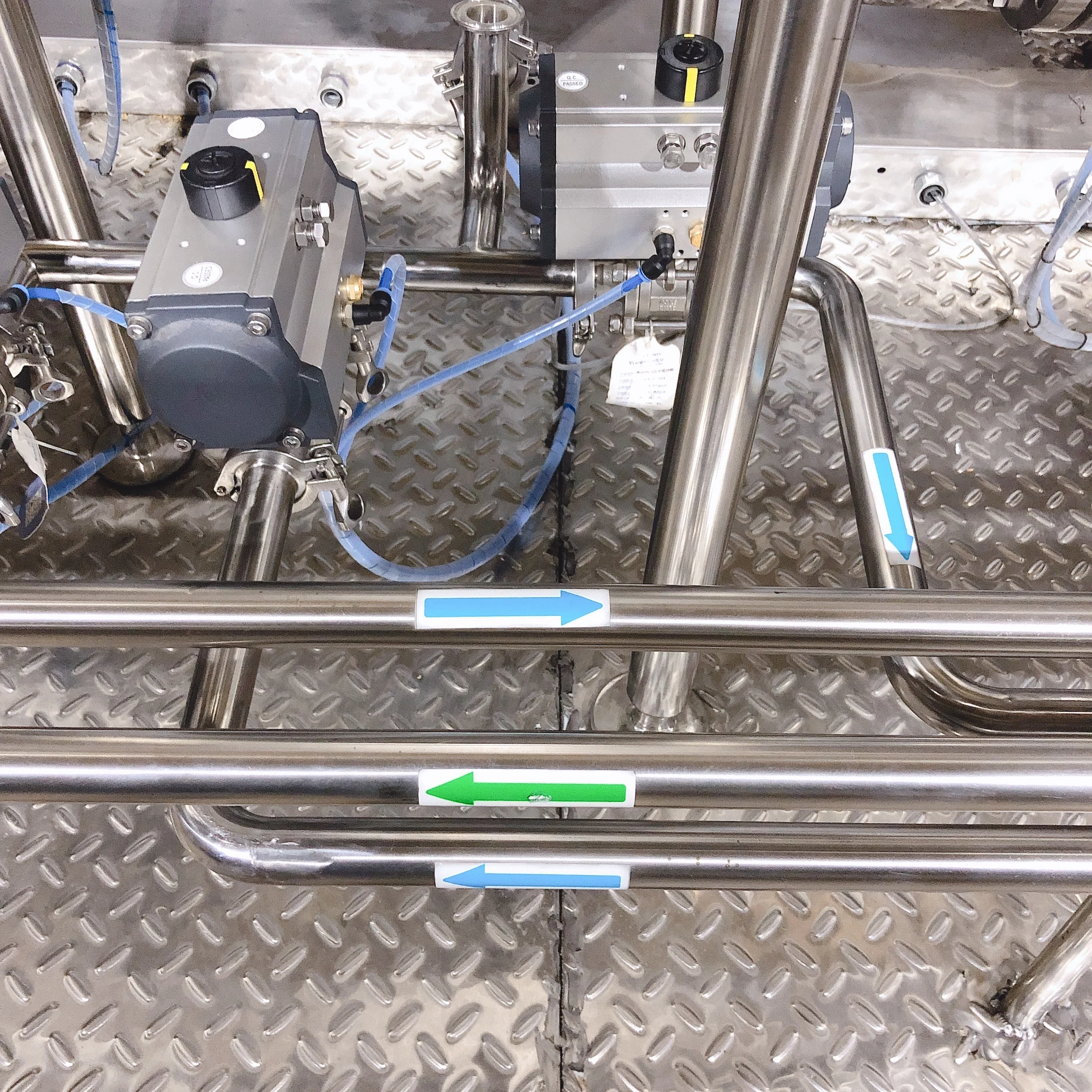

2.Oil or water separator

3.Sight glass

4.Vacuum switcher

5.Cooler

6.Hot backset current condenser

7.Butterfly valve

8.Defoamer machine

9.Reflux pipe

10.Butterfly valve

11.Concentrating Evaporator

12. Heater

13.Sight glass

|

Model

|

GK-0.1/25

|

GK-0.3/75

|

GK-0.5/125

|

|

The volume of extracting (m³)

|

0.1

|

0.3

|

0.5

|

|

The work temperature of extracting and concentrating (°C)

|

Water: 50-90°C Alcohol: 40-80°C

|

||

|

Raw Material Input Capacity (kg)

|

10-15

|

30-45

|

50-70

|

|

Capacity of Concentrating Evaporator

|

25kg/hour

|

75kg/hour

|

125kg/hour

|

|

Power of Vacuum Pump

|

2.2kw

|

2.8kw

|

3.5kw

|

|

The time of extraction (h)

|

6-8

|

||

|

Concentrate density (%)

|

1.2-1.35

|

||

concentrating, the water extracting is control in 50℃-90℃, ethanol extracting is control in 40℃-80℃. Because of the low

extracting, it can avoid the Chinese herbal materials active ingredient, especially the organisms activated not easy to

destroy, at the same time it can avoid producing the inefficacy ingredients in the high temperature, such as dextrin, colloid,

tannin etc, improve the products quality, convenient for isolation and purification.

High Drawing Rate:

Because of the extracting pot at the condition of the vacuum pressure and low temperature, it can enable the Chinese herbal materials cell to expedite expand, cell membrane broken at once, at cell inside, it stripping the active ingredient. And the continuously supplement of the reflus-norma new solvent, which it enable the solvent played at the herbal materials surface and penetrate into the herbal materials interior, improve the herbal attrition elution-force and the solubility, the herbal material and the solvent keep higher gradient of concentration and extend ability, having accelerated the dissolving out of solvent of active principle of the herbal materials ,improve the extracting rate and the harvested ointment rate of the Chinese herbal material.

Save The Solvent: Only need to join 8 times of solvents of crude materials quantity once, utilize new solvent conduct of hot backset current to hot backset current to supplement, which the backset total is equal to the old extracting need 2-3 times join solvent total, it save the solvent 50%-60%, also it can increased the collecting volume of herbal materials.

Hot Tags: dye extraction solution, China dye extraction solution manufacturers, suppliers, factory